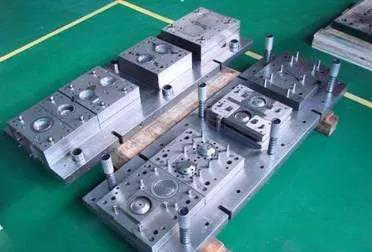

Develop a mold from design to manufacturing and then used to produce debugging success takes a lot of manpower and financial resources,I believe all enterprises attach great importance to the life of mold,We hope that developed after mold can produce more parts,Maximize its role,Achieve maximum economic benefits。Improve the quality of mold material must be selected,Using different materials for the respective heat treatment process and the optimization process,Improve the manufacturing precision and service life of the mold,To avoid the occurrence of early failure of the mold。

The following major measures for the analysis of the factors affecting the life of the die and extend the life of。

One、Analysis of factors affecting the life of the die

Mold design and production process

Poor surface quality mold parts、Large tolerance、Unstable material properties and surface impurities,Mold can lead to accelerated wear and tear。In the drawing die,Deep-drawn sheet metal forming ability、thickness、Effect of the surface quality of the material and the size of the mold pressing load tends adhesion degree。Because of the uneven angle-piece mold can cause stress concentration leading to mold cracking,The shape and size of the concavo-convex mold radius greater impact on die wear,In the drawing die as a relatively small radius fillet,It will increase the flow resistance of the blank,Further increasing frictional wear of the mold or breakage of the workpiece。

Mold part material、Hardness and metallurgical quality

Effect of mold material properties of the parts of the die life greatly,Therefore, we must choose a reasonable mold parts of the material。

It refers to the compressive strength of the main mold hardness of tool steel、Abrasion resistance and ability to bite,Mold hardness while generally reducing Toughness、And thermal fatigue resistance can grinding performance。therefore,Hardness is too high often lead to fracture failure of the mold。

Metallurgical large mass of mold material、Medium mold section and a high content of alloying elements and carbon steel mold influenced,The performance of non-metallic assimilation、Carbide segregation、And loose intermediate。

Heat treatment process of the mold

Pre-heat treatment、Stress relief annealing after the rough、Quenching and tempering、After grinding or EDM stress relieving heat treatment and the like belonging to a mold,Effect of heat treatment on the quality of the performance and the lifetime of the mold is also a great。

Die Process

Machining、Grinding and EDM manufacturing process is necessary for the mold,Production die wear resistance Effect、Fracture resistance、strength,If the wrong processing methods,Processing quality prone to problems。Such as:Improper die grinding process reduces fatigue strength and fracture resistance;Improper EDM die reduces the toughness and fracture resistance。

two、Measures to extend the service life of the die

Correct choice of mold material

Working conditions worse than the punch die,The material should be better,When large quantities of punching,To select high intensity、Good wear resistance、Good toughness mold material。

Reasonable die structure

Beginning of the design must ensure that the toughness of the mold、Stiffness and strength,Blanking process to ensure that the projections、Die and other structures will not be deformed due to the influence of forces occurring blanking、Increase the degree of damage or wear。Mold design should maximize the use of guide means,Should be considered mold part gap。

Good lubrication conditions

Good lubricity of the mold may have a rust-proof function,But also reduce the friction heat、Friction、Pressforce,Reduce mold wear,Extend the life of the mold。

Processing and assembly quality die

Life is directly proportional to its precision and quality dies,The higher the precision and quality of its service life longer。

Rational use and maintenance of mold

When using a mold,You should choose the right、High precision stamping equipment。In the stamping process,Frictional resistance during cold forging blanks should be subject to the phosphate or copper plating process to reduce operating,Prevention of adhesion of mold nip,Therefore, prior cold upsetting a metal plate must be preheated to improve the processability of the material。Lubricated surface finish cold forging metal sheet can be increased,Reduce frictional resistance,Reduce wear,Extend the life of mold。

When the mold storage,on、Should maintain a certain gap between the lower die,To protect the cutting edge is not damaged。When stamping,The depth of the punch into the die should be reasonable,So as not to wear increased。After a period of time stamping,Raised、Die edge wear phenomenon occurs,Should be timely repair mode,To avoid wear and tear of the die and the punch edge additional moment caused by uneven gaps。Edge punch and die again after grinding,More uneven edge gap,At this time, the cutting edge should be finely ground to a fine whetstone、polishing,Removal of grinding burr,To achieve the surface roughness values generally less Ra≤0.10μm,Can instantly eliminate the unevenness of the mold edge wear and risk。

Go to:Public number (mold industry)

Dana Mold Co., Ltd. is based Datang mold industry upgrading and development from the professional mold manufacturing enterprises,It has 20 years of production history mold。

Dana Mold Co., Ltd. is based Datang mold industry upgrading and development from the professional mold manufacturing enterprises,It has 20 years of production history mold。